The EasyLan® H.D.S. system combines ease of installation and maintenance better than any other trunk cabling system on the market. Save up to 30% of the costs and 75% of the installation time when cabling your IT infrastructure.

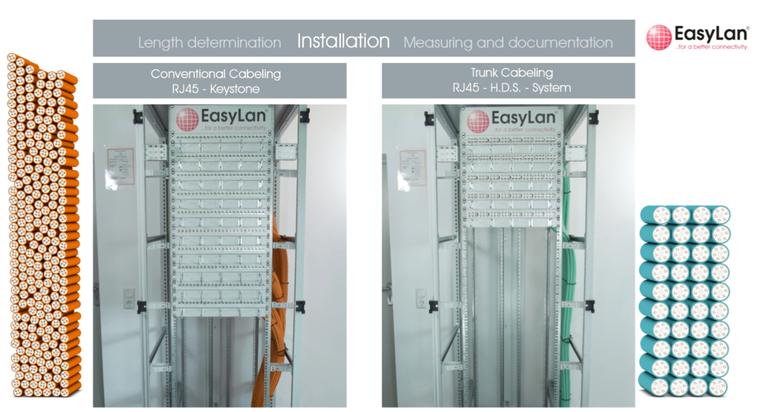

The following animation shows the neutral cost and installation time comparison of the conventional cabling with the H.D.S. trunk cabling with respect to the length determination, the installation and the measurement & documentation.

Plug and Play

All components of the H.D.S. system are pre-configured at the factory in accordance with the highest quality specifications and will be delivered together with clearly allocatable measuring reports. Therefore, configurations or other dwell times are not required in the data center. Contaminations at sensitive glass fiber connections are therefore prevented.

Climate friendly and continuous

The cable diameter using an H.D.S. - AWG23 trunk cable (fig. 1) is approx. 18 mm (AWG23, B2ca) and is about 30% less when installed than using a conventional individual cabling (fig. 2) with approx. 8 mm (AWG23, B2ca). This reduces the air resistance and the fire load in the distributor cabinet, therefore, the air conditioning can be used optimally with respect to demand. The maximum cable length for the H.D.S. - AWG23 trunk cable is 90 m and for the H.D.S. - AWG26 trunk cable (cable diameter: 13.90 mm) it is 60 m.

Trunk cable types

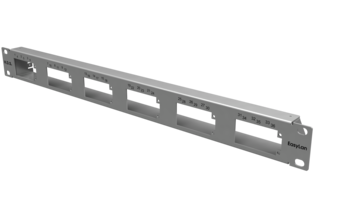

H.D.S. - Panel

Accessories

Patch Cords

Variants

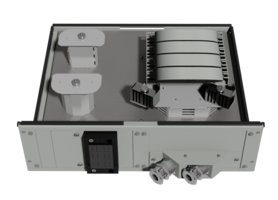

H.D.S. – Splice cabling

The perfect separation between splicing area and patch area

Characteristics

- central transfer point of the backbone cables to flexible (3 mm) 12-fiber H.D.S. pigtails

- distributed cabinet cabling

- better air conditioning, because splicing boxes are not required

- very high packaging density with 336 outlets to 3 HE